Factors to Evaluate When Purchasing the Right Chemical Defoamer for Your Operations

Factors to Evaluate When Purchasing the Right Chemical Defoamer for Your Operations

Blog Article

Discovering the Benefits of a Chemical Defoamer in Production and Manufacturing

The integration of chemical defoamers in manufacturing and manufacturing procedures supplies a strategic advantage by addressing one of the relentless obstacles in commercial procedures: foam control. As makers aim to enhance procedures and improve client fulfillment, the function of chemical defoamers comes to be significantly essential.

Significance of Foam Control

While the presence of foam in producing procedures can sometimes seem safe, efficient foam control is vital for maximizing operational performance and item high quality. Foam can hinder various phases of manufacturing, leading to ineffectiveness that might prolong and increase expenses handling times. In sectors such as food and drink, drugs, and chemicals, unrestrained foam can block equipment, interrupt automated systems, and ultimately lead to item inconsistencies.

Applying efficient foam control approaches not just improves performance but additionally supports regulative compliance in markets where foam can cause ecological problems. By utilizing chemical defoamers, suppliers can minimize these difficulties, making certain smoother operations and higher-quality output. Inevitably, prioritizing foam control is a crucial facet of manufacturing that can generate significant advantages in terms of security, performance, and item integrity.

Sorts Of Chemical Defoamers

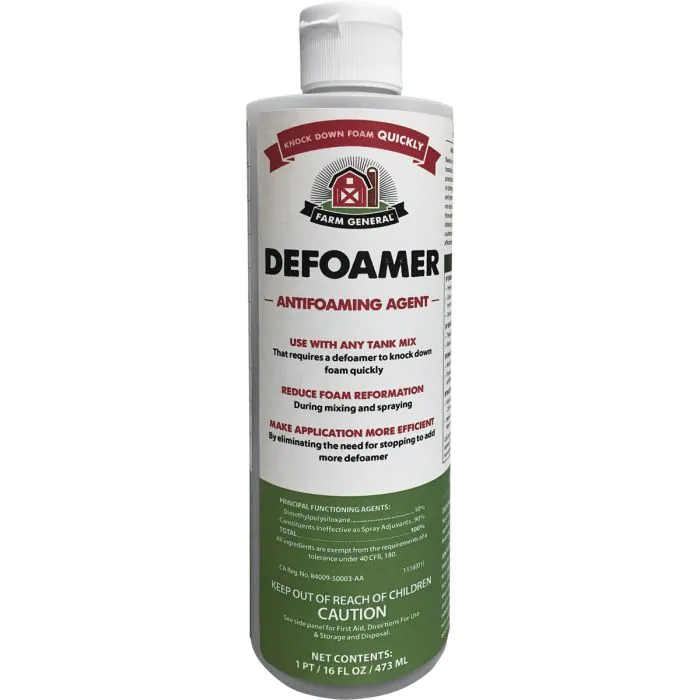

What types of chemical defoamers are available for making processes, and how do they differ in application? Chemical defoamers can be classified into 3 main kinds: silicone-based, organic, and inorganic defoamers. - Chemical Defoamer

Organic defoamers, normally obtained from all-natural oils or fats, work in a series of applications, including food and drink production. They are typically liked for their lower poisoning and environmental effect, making certain conformity with market laws.

Each sort of defoamer serves distinct functions based on the chemical make-up and the specific needs of the manufacturing procedure, allowing manufacturers to choose one of the most ideal option for their certain demands.

Benefits in Production Efficiency

Chemical defoamers play a critical role in boosting manufacturing performance by effectively regulating foam generation throughout various processes. Foam can impede production prices, interfere with equipment procedure, and bring about expensive downtime. By including chemical defoamers, producers can alleviate these concerns, making certain smoother process and raised general performance.

Making use Read Full Article of chemical defoamers helps enhance the functional performance of devices such as pumps, reactors, and mixers. With minimized foam, these devices can operate at their meant capability, lessening the threat of overflow and enabling constant handling. This leads to much better source application and higher throughput.

Furthermore, chemical defoamers assist in faster processing times by more information lowering the moment needed for foam elimination. This acceleration can dramatically impact manufacturing routines, allowing producers to satisfy consumer demand better. Additionally, making use of defoamers contributes to decrease power intake, as machinery runs much more efficiently with decreased foam disturbance.

Effect On Item High Quality

Foam control is not just essential for keeping efficiency in making processes but likewise plays a substantial function in making certain item quality. Too much foam can introduce air into formulas, causing disparities in the final item. This can show up as problems such as gaps, uneven structures, or poor finishes, which weaken the designated high quality and efficiency of the product.

Moreover, foam can impede the homogeneity of mixtures, causing unequal circulation of energetic components. In sectors such as finishes, cosmetics, and food production, this can cause variations in color, preference, and overall effectiveness. By using a chemical defoamer, manufacturers can alleviate these dangers, ensuring that items meet rigorous high quality specs.

Furthermore, regulating foam can enhance the stability of solutions and suspensions, which is vital for making sure shelf-life and customer contentment. With enhanced product uniformity and minimized problems, producers can achieve higher standards of top quality guarantee, inevitably causing raised customer trust fund and brand name loyalty.

Cost-Effectiveness and ROI

Effective foam control not just enhances product top quality however also adds substantially to the overall cost-effectiveness of manufacturing procedures. The use of chemical defoamers lessens foam-related issues, which can or else result in production hold-ups, equipment breakdowns, and enhanced energy consumption. By decreasing foam, producers can enhance their processes, causing higher throughput and performance.

Buying chemical defoamers can yield a substantial return on investment (ROI) The initial costs linked with these ingredients are typically countered by the financial savings recognized from decreased downtime and improved material yield. Enhanced item top quality can reduce waste and revamp costs, further strengthening financial performance.

In enhancement, reliable foam control can result in reduced water and power use, contributing to lower functional prices. This is especially crucial in sectors where source effectiveness is vital. By incorporating chemical defoamers right into their processes, manufacturers can attain lasting savings while maintaining competitive pricing in the marketplace.

Final Thought

In final thought, the assimilation of chemical defoamers in manufacturing and production procedures is vital for maximizing operational performance and boosting product quality. The advantages provided by chemical defoamers not only sustain regulative compliance but also supply an affordable edge in the manufacturing landscape.

The integration of chemical defoamers in manufacturing and production procedures provides a critical advantage by attending to one of the persistent challenges in industrial procedures: foam control.While the presence of foam in producing processes can sometimes seem harmless, reliable foam control is pop over to this web-site critical for optimizing functional performance and item high quality.Chemical defoamers play an important role in boosting making performance by effectively managing foam generation throughout different processes.Moreover, chemical defoamers help with faster processing times by reducing the time needed for foam removal. Additionally, the use of defoamers contributes to reduce power consumption, as machinery runs much more effectively with reduced foam interference.

Report this page